Cerabest

| Uno | Due | Tre |

|---|---|---|

| Main component | Aluminia oxide (AL2)(O3) | 90% |

| Modulus of rapture at 20°C | (Kg/m2) | 31,6 x 10^6 |

| Modulus of rapture at 1300°C | (Kg/m2) | 2,3 x 10^6 |

| Tensile strength | (Kg/m2) | 17,6 x 10^6 |

| Density | (Gr/cm2) | 3,65 |

| Hardness | (Mohs scale) | 9 |

| Hardness | (Rockwell 45N) | 79 |

| Pressure | (Kg/cm2) | 21.000 |

| Resistance to bending stress | (Kg/cm2) | 2700 |

| Elasticity | 2,7 x 10^6 | |

| Color | White | |

| Porosity | 0 | |

| Coefficient of expansion | ||

| From 20° To 200° | 5,80 x 10^6/°C | |

| From 200° to 500° | 6,47 x 10^6/°C | |

| From 500° From 800 | 6,99 x 10^6/°C | |

| From 800° From 1000 | 7,42 x 10^6/°C | |

| From 1000° From 1200 | 7,84 x 10^6/°C |

| Diametro interno Inside diameter | Diametro esterno | Pressione di esercizio Working Pressure | #colspan# | #colspan# | Pressione di scoppio Burst Pressure | #colspan# | #colspan# | Raggio minimo di curvatura | Peso unitario | ||||

|  |  | #colspan# | #colspan# |  | #colspan# | #colspan# |

|

| ||||

| mm | mm | Mpa | psi | bar | Mpa | psi | bar | mm | Kg/mt | ||||

| 25 | 49 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 375 | 2,59 | ||||

| 32 | 56 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 480 | 3,07 | ||||

| 38 | 62 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 570 | 3,48 | ||||

| 42 | 66 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 630 | 3,75 | ||||

| 48 | 72 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 720 | 4,17 | ||||

| 50 | 74 | 1,0 | 150 | 10 | 30 | 448 | 30 | 750 | 4,31 | ||||

| 60 | 86 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 900 | 5,27 | ||||

| 63,5 | 90 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 953 | 5,54 | ||||

| 70 | 100 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 1050 | 6 | ||||

| 75 | 105 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 1125 | 6,35 | ||||

| 80 | 110 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 1200 | 6,93 | ||||

| 100 | 132 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 1500 | 8,56 | ||||

| 114 | 147 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 1710 | 13,24 | ||||

| 125 | 158 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 1875 | 14,42 | ||||

| 150 | 188 | 1,0 | 145 | 10 | 3,0 | 448 | 30 | 2250 | 19,42 | ||||

| 200 | 240 | 1,0 | 150 | 10 | 3,0 | 448 | 30 | 3045 | 27,68 | ||||

SUBSTRATE: SBR/NBR rubber pipes are lined with Hexagonal Ceramic Mosaic. The use

of rubber enables the pipes to be highly flexible and since it is lighter than steel can be

installed into difficult to reach areas much easier than it is to install the steel equivalent. Good resistance to some chemicals (please contact our technical support before specific applications). Ceramics segments are composed of aluminia and oxide are produced with the most advanced technology, sintering spray-dried powders. The special manifacturing process allows to obtain a very compact structure (porosity 0) and extreme hardness (Mohs scale 9).

The special surface guarantees a perfect flow of the material, avoiding any problem related to packing and oxidation

REINFORCEMENT: Reinforced with a continuos steel spiral to ensure that the diameter of the pipe is maintened no matter how it’s bent. Strips of copper also run downthe length of the rubber pipes to prevent a build up of electrostatic.

COVERING: Black, antistatic (R=2.0 M/m), based blend of SBR/NBR, resistant to abrasion and atmospheric agents.

Suitable for pneumatic conveyng (suction and discharge) in industrial applications of dry cement, coal, and RDF (refuse derived fuel from the recovery, synergistic to coal dust), minerals, ceramic powder, glass fiber, and the load of tanks, and storage ware houses and silos.

Applications in the following following industries : steel mills, coking plants, power plants and factories of ceramic, glass, insulation materials an cement etc…

WORKING TEMPERATURE :

-30°C (-22°F) TO +70°C (+158°F)

STANDARD LENGHT :

From 10 mt. up to 20 mt.

PACKAGING:

Wrapped in polyethylene film

TOLLERANCES :

RMA steel mandrel

On internal diameter :

< = d.i. 38 mm : +/- 0,79 mm > = d.i. 38 mm : +/- 1,59 mm On lenght : +/- 1%

N.B.

Available on request CERABEST HT : high temperature version resistant up to 530 °C (+986°F)

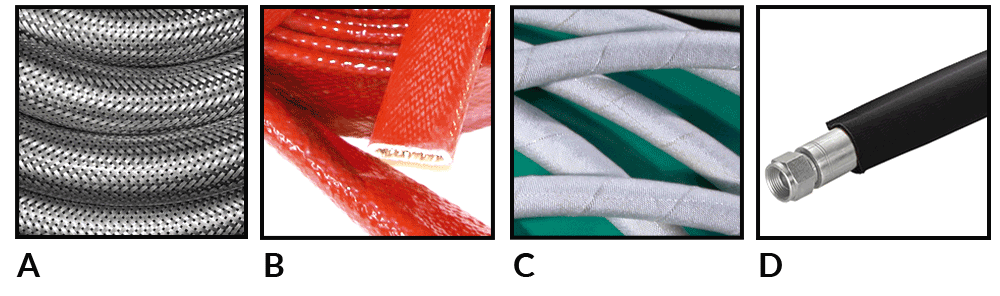

A- Calza acciaio zincato / acciaio inox

B- Calza fibra di vetro siliconata

C- Calza fibra di vetro

D- Calza in tessuto protettiva