EN 853 2SN – SAE 100 R2 AT

Inner tube: Oil resistant synthetic rubber.

Reinforcement: 2 high tensile steel wire braids.

Cover: Abrasion, weather, ozone and oil resistant synthetic rubber.

Temperature range: -40° + 100° with peak of + 125°

Inner tube: Oil resistant synthetic rubber.

Reinforcement: 2 high tensile steel wire braids.

Cover: Abrasion, weather, ozone and oil resistant synthetic rubber.

Temperature range: -40° + 100° with peak of + 125°

| Diametro nominale Nominal Bore | Diametro interno | Diametro esterno | Pressione di esercizio | Pressione di scoppio | Raggio minimo di curvatura | Peso unitario | ||||||

|

|

|

|

|

| |||||||

| mm | mm | inch | mm | bar | psi | bar | psi | mm | Kg/mt | |||

| 5 | 4,8 | 3/16” | 13,1 | 415 | 5920 | 1660 | 23880 | 90 | 0,300 | |||

| 6 | 6,4 | 1/4” | 14,6 | 400 | 5800 | 1600 | 23200 | 100 | 0,355 | |||

| 8 | 7,9 | 5/16” | 16,3 | 350 | 5000 | 1400 | 20000 | 115 | 0,420 | |||

| 10 | 9,5 | 3/8” | 18,7 | 330 | 4800 | 1320 | 19200 | 130 | 0,520 | |||

| 12 | 12,8 | 1/2” | 21,8 | 275 | 4000 | 1100 | 16000 | 180 | 0,610 | |||

| 16 | 16 | 5/8” | 25,0 | 250 | 3630 | 1000 | 14920 | 200 | 0,720 | |||

| 19 | 19 | 3/4” | 29,0 | 215 | 3120 | 860 | 12480 | 240 | 0,945 | |||

| 25 | 25,8 | 1” | 36,9 | 165 | 2400 | 660 | 9600 | 300 | 0,131 | |||

| 31 | 31,8 | 1”1/4 | 46,7 | 125 | 1820 | 500 | 7280 | 420 | 1,900 | |||

| 38 | 38,1 | 1”1/2 | 53,2 | 90 | 1320 | 360 | 5240 | 500 | 2,250 | |||

| 51 | 50,8 | 2” | 65,9 | 80 | 1160 | 320 | 4640 | 630 | 3,100 | |||

| 64 | 64 | 2”1/2 | 83 | 70 | 1000 | 280 | 4000 | 760 | 3,960 | |||

| 76 | 76 | 3” | 96 | 55 | 800 | 220 | 3200 | 900 | 4,960 | |||

Hydraulic mineral and “biological” oils, polyglycol base oils, water, oil/water emulsions.

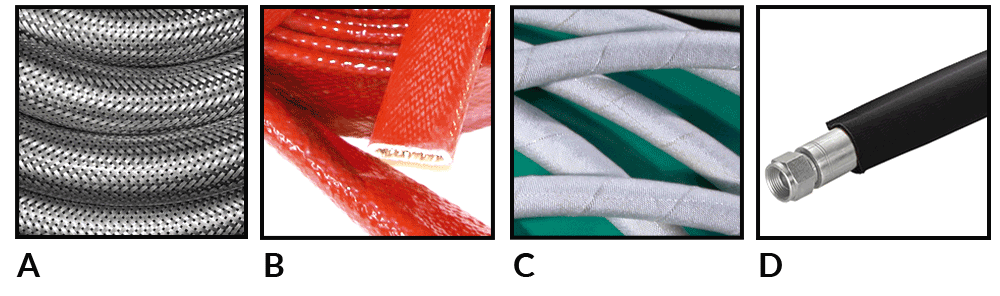

A- Galvanized and stainless steel braids

B- Fiber glass braid + red silicone

C- Fiber glass braid

D- Textile protective braid